The packaging segment — folding carton, flexible, corrugated and labels — has primarily used conventional printing technologies, such as screen, flexo, offset and gravure. Screen printing’s versatility, for example, has often supported the leading conventional technologies with regard to pre-printed white, brilliant or vivid colors, varnish and high or low tactile. But what about the rise of inkjet, and its application in label printing?

The packaging segment — folding carton, flexible, corrugated and labels — has primarily used conventional printing technologies, such as screen, flexo, offset and gravure. Screen printing’s versatility, for example, has often supported the leading conventional technologies with regard to pre-printed white, brilliant or vivid colors, varnish and high or low tactile. But what about the rise of inkjet, and its application in label printing?

When Indigo introduced their first digital printer, less than 10% of the total volume of labels were digitally printed. This technology had some hurdles to overcome to become a significant player in the packaging industry. As with any industry, there were questions of the investment price vs. profit and what type of technology was appropriate for the job (short vs. medium/long runs), among other considerations. Just a couple of years later, however, the conventional flexo label printers were convinced by the benefits inkjet/hybrid label printers were offering the early adopters.

Considerations

A rise in inkjet can be attributed to the similarity between the ink deposit and resolution of flexo and inkjet. The variable sizes of commercial print jobs have forced the label maker to find a way to profitably print both a short and a mid-to-long production run as the average run length becomes gradually shorter.

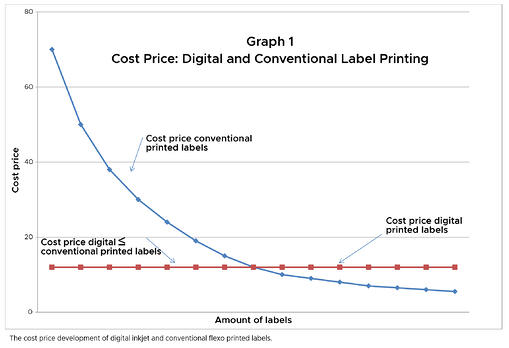

For cost considerations, digital print speeds may be slower than conventional print, and the cost per liter of inkjet ink may be substantially higher than conventional ink. In short runs, however, digital wins on cost per unit:

Comparing Technologies

Conventional flexo printing needs an extended setup and lead time. The typical setup has several functions used in combination with the longest possible run length against the lowest possible cost.

Conventional flexo printing has five, six, seven, eight, etc. colors, possibly including white and other spot colors. It includes a number of back print stations, combined with a turner bar, a die-cut station, pre-coat station, cold foil, lamination and rotary screen, completed with an unwind and a rewind. This setup is for a typical long run (more than 12,000 labels) application.

A stand-alone inkjet press is a separate collection of CMYK digital inkjet print stations, with some spot colors completed with an unwind and a rewind. The stand-alone inkjet printing process may be completed with finishing units, such as a die cutting, varnishing, foiling and lamination. Separating the printing part from the finishing applications may substantially impact productivity. Inkjet printing is a typical short-run application, up to a maximum of 1,300 labels.

Hybrid printing is a smart combination of the best characteristics of conventional flexo and digital inkjet printing in one line, or positioned on one platform, to expand the stand-alone digital inkjet application. The mid web hybrid label printer is completed by in-line finishing, which does not affect the productivity of each individual print technology.

It’s worth noting when referring to narrow-, mid- and wide-web printers, the exact width is arbitrary, and can only be given by estimation. Narrow web refers to smaller than 18 inches, mid ranges from 18 to 40 inches, and wide web is wider than 40 inches. Label printing is a typical narrow-web application. Most inks have been developed, in terms of speed, for narrow-web printing (a few hundred feet per minute), rather than the speed of wide web (1,000 feet per minute).

It’s worth noting when referring to narrow-, mid- and wide-web printers, the exact width is arbitrary, and can only be given by estimation. Narrow web refers to smaller than 18 inches, mid ranges from 18 to 40 inches, and wide web is wider than 40 inches. Label printing is a typical narrow-web application. Most inks have been developed, in terms of speed, for narrow-web printing (a few hundred feet per minute), rather than the speed of wide web (1,000 feet per minute).

Current Market

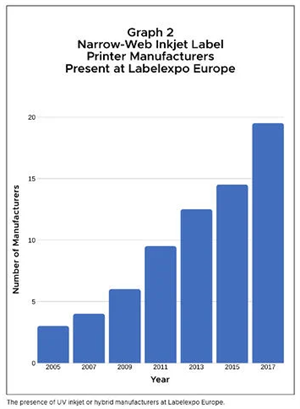

The rise of inkjet is evident in the increasing presence of narrow-web inkjet manufacturers present at Labelexpo Europe (Graph 2), and the number of joint ventures during its development has been remarkable. What was once a technology with serious doubts in the mid-to-late 2000s, now has a clearer presence we continue to monitor.

Read more on the digital vs. conventional label printing debate.