Traditionally, cellulose nanofiber (CNF) production has primarily relied on new cellulose sources. Yet, the shift to using reused cellulose sources, including paper mill sludge (PMS) for CNF underscores the significance of reusing and recycling industrial byproducts.

PMS contains significant amounts of cellulose that can be extracted as a raw material. The purpose of present study is to provide a sustainable approach to PMS utilization as a paper coating additive in the cellulose nanofibrils (CNFPMS) form via simply scalable wire-wound rod coating method. The effect of CNF PMS additive amounts at two coating layers on microstructure and surface properties of coatings such as porosity, air permeability surface roughness and optical properties such as brightness, gloss and print output (CIE L*a*b*) is studied. They can also provide insight for the eventual print performance.

Results indicated that the obtained CNFPMS in paper coating shows a decrease in porosity, presenting significant improvement in the coating microstructure. A marginal increase in in permeability coefficient and surface roughness suggest improving color reproduction and preventing color density losses while leveraging G7-based print optimization. Further optical analysis showed slight decrease in brightness and gloss, as was expected. Notably, the lightness was improved, which also indicates increasing color gamut volume in printing applications. As a result, the current work offers a sustainable approach to manage PMS for use in paper coatings as a high-value-added material.

Excerpt:

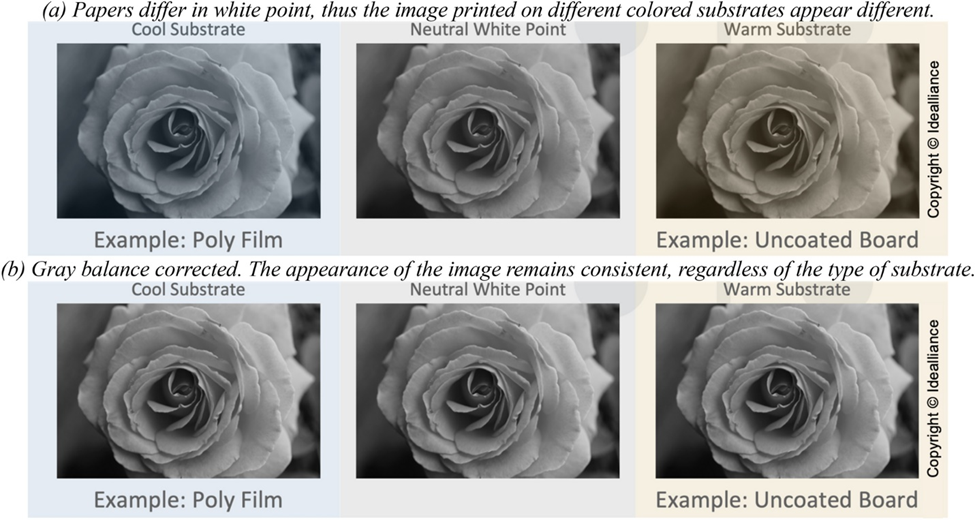

Moreover, the influence of paper color in the color printing applications is manageable by following procedures used for reproducing visually accurate colors, such as G7 (Copyright Idealliance and include G7 is a registered trademark of Idealliance), thanks to the grayscale colorimetric measurements between processes and/or various papers53. In general, papers differ in white point, thus images printed on different colored papers appear slightly different (Fig. 5a). Applying G7 calibration and process control methodology (Copyright Idealliance and include G7 is a registered trademark of Idealliance) and its Substrate Corrected Color Aim (SCCA) procedures, near neutral gray balance and common appearance on any substrate can be achieved (Fig. 5b)54. (source: Addition of fibers derived from paper mill sludge…, Bilge, et al.)

Become a G7 Expert at upcoming G7 Expert Training & Certification. Learn more here.