Vietnam's Leading Global Printing Solutions Provider: Powered by the G7 Certified Quality Framework

Located in Hanoi, Vietnam, Capital Packaging (https://en.capitalpackaging.vn) is a pioneering company supporting the 'China Plus One' strategy, aimed at diversifying supply chain risks by establishing production bases outside of China for global brands. As the first company in Southeast Asia to support G7+™ Expert training, Capital Packaging had three employees certified as Idealliance/PRINTING United Alliance G7+ Experts this past October. Specializing in packaging printing services for leading global electronics brands, the company has a core competency in implementing and maintaining a G7® certified quality framework, allowing it to deliver the highest quality and service to customers in Vietnam and beyond.

Mr. Do Vu Anh, Technical Advisor at Capital Packaging, who studied printing at the Hanoi University of Science and Technology, has been a key figure in Vietnam's printing industry for over 20 years. From providing cutting-edge printing solutions to now overseeing color management, he emphasizes that the company’s success lies in a structured production and quality management system, along with a strong commitment to employee training and capacity building. Mr. Do believes that the skills and knowledge he has cultivated since studying printing technology have been invaluable assets, propelling both his personal growth and the advancement of Vietnam’s printing industry.

Idealliance Southeast Asia’s Managing Director Ms. Hye-Jeong Ahn, recently sat down with Mr. Do Vu Anh to discuss the work of Capital Packaging and their approach which has allowed them to become a leading global print solutions provider.

Hello, thank you for taking the time to do this interview. First, could you tell us a little about yourself, how you entered the printing industry, and how you came to work at Capital Packaging?

Hello, my name is Do Anh Vu, and I am the Head of Colour Management at Capital Packaging. It’s a pleasure to be here.

I began my journey in printing in 2002 when I enrolled at Hanoi University of Science & Technology (HUST) to major in printing technology. After graduating, I had the opportunity to work at one of the most renowned publishing printing companies in Hanoi. Working there for over three years, I gained valuable insights from highly experienced and passionate colleagues who taught me so much about the craft.

In 2006, I joined Ferrostaal and became part of the team responsible for the Manroland sheetfed press investment and installation project. This role allowed me to learn about the latest equipment features and systems, essential for improving and stabilizing offset printing quality. I also gained practical knowledge about equipment maintenance to ensure high operational readiness.

From 2013 to 2021, I worked as a project manager at Rieckermann, a leading provider of printing solutions in Vietnam, working with renowned brands like Heidelberg and X-Rite. There, I deepened my understanding of color management and, importantly, learned how to build stable production processes that meet various print color standards and targets.

Since 2021, I have been with Capital Packaging, overseeing color management and applying all I’ve learned to support our team and our clients.

Could you describe your role at Capital Packaging and provide an overview of your current production workflow?

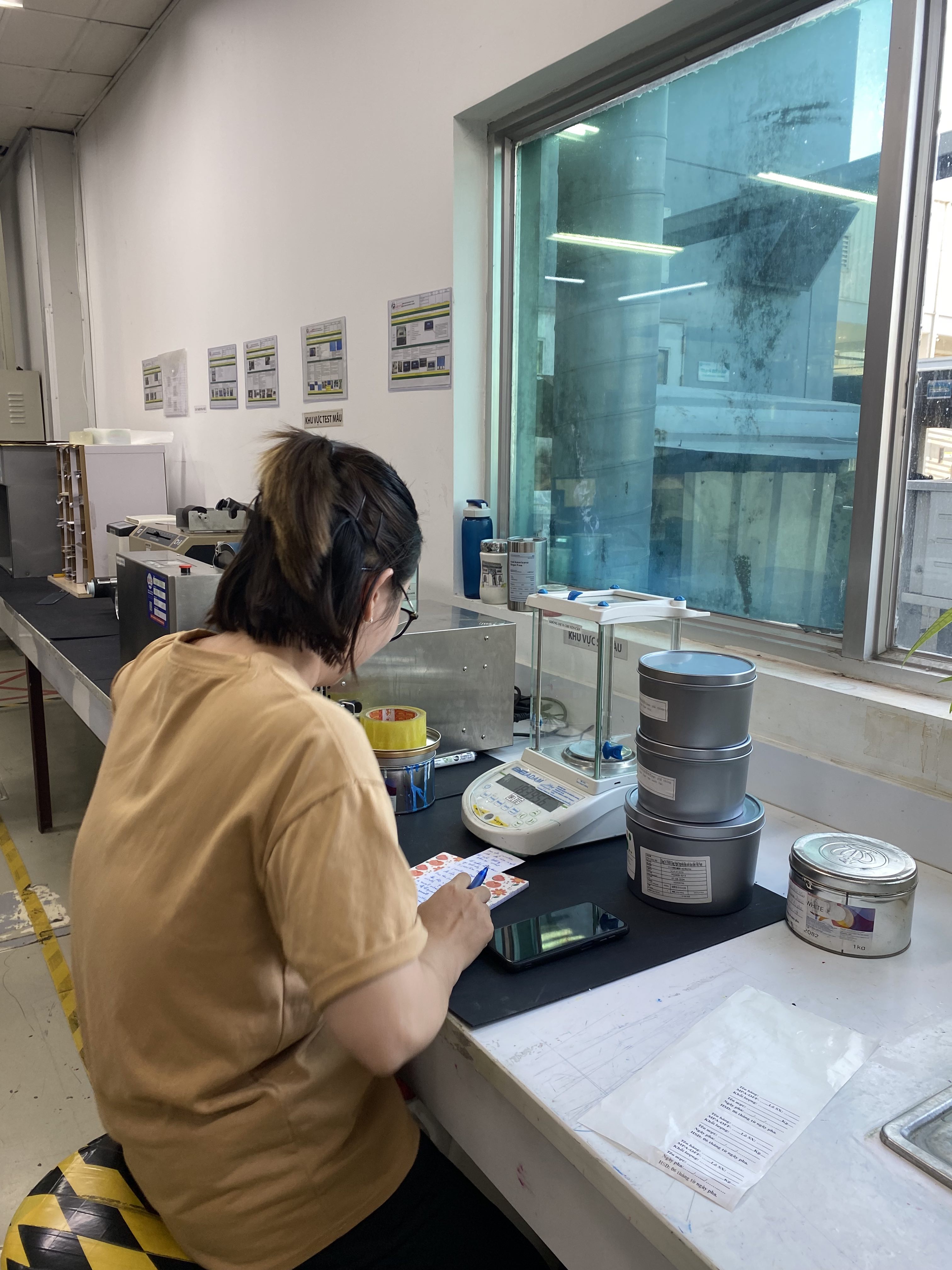

As Head of Colour Management, my role involves overseeing all color-related processes. I am responsible for implementing G7 standards, conducting G7 calibration tests, managing color consistency, ensuring quality control, and planning for our clients, who are primarily in the electronics sector. Since last year, I've also been responsible for expanding our services into publishing printing, in addition to packaging, and for promoting the company.

Our color workflow is powered by Heidelberg printing systems and supported by essential software such as Curve4, GMG, and ColorTool Box. We integrate hardware devices from Kodak, Epson, X-Rite, Azo, Heidelberg, and Koenig & Bauer. At the core of our workflow are our enthusiastic and dedicated employees, who are constantly eager to learn and work hard to uphold our high standards.

Capital Packaging is known for its excellent print quality and customer service. Could you provide a brief history of the company, outline its main business activities, and highlight some of its key customers?

Capital Packaging was established in 2007 and has specialized in paper packaging printing for over 16 years, primarily serving industrial customers in northern Vietnam. Our focus is on meeting the needs of both local brand owners and global electronics companies.

To optimize pricing, we source paper directly from international mills and maintain a reliable local network to fulfill small or urgent orders. Leveraging our experience with electronics brands, we also source specific papers, inks, and varnishes from Chinese suppliers, supporting the "China Plus One" strategy for global clients.

We operate within a G7 certified quality framework, integrating MIS/ERP systems to ensure globally aligned quality assurance and standardized workflows that meet the high demands of our clients. Additionally, our expertise in exports and compliance enables us to support both international and foreign direct investment (FDI) customers with extensive experience in export protocols.

Our key offerings include folding cartons made from flute board box (FBB) and solid bleached sulphate (SBB) solutions for daily consumer goods, toys, and electronics brands, labels primarily serving FMCG clients via an automated packaging line, and rigid boxes, initially developed for electronics brands but now expanded to offer kitting for diverse clients. Recently, we ventured into publishing with a focus on board books for global supply chains, showcasing our printing capabilities.

Capital Packaging provides printing services to customers in Vietnam and globally. Could you share your business strategy and vision, and explain the efforts you're making to support your Vietnamese and international customers?

Our vision at Capital Packaging is to become Vietnam's leading local printing solutions provider. We pursue this vision through four key strategies.

- First, we invest in advanced technology and best practices, ensuring we adopt the latest innovations and adhere to global industry standards, keeping us competitive and capable of delivering top-quality solutions.

- Second, we prioritize environmental and social sustainability, committing to practices that meet industry expectations, benefit our communities, and protect the environment, ensuring long-term operational integrity.

- Third, we cultivate a customer-centric culture. We're reshaping our organization so every team member is focused on delivering outstanding service and customized solutions.

- Fourth, we strive to support both domestic and international clients. For our global customers, we aim to be a seamless, dependable partner in Vietnam, ensuring peace of mind through adherence to global supply chain standards. For our Vietnamese customers, we help boost competitiveness by providing access to global best practices and innovations, positioning ourselves as a solutions provider that aligns with international trends in printing and packaging.

What requirements do Capital Packaging’s local and international clients have, and how do you prioritize and meet their quality and service expectations?

Our international clients have stringent requirements, especially regarding precise color management, such as tight Delta E control for brand spot colors and consistent color reproduction across production batches. To meet these high standards, we use the G7 framework, which provides a structured approach for achieving predictable, high-quality results. This framework not only aligns us with global standards but also strengthens Vietnam’s position in the international supply chain.

Our primary focus areas for quality and service include a comprehensive quality assurance program and effective client communication. We’ve implemented quality control at every production stage—Incoming Quality Control (IQC), Process Quality Control (PQC), and Final Quality Control (FQC). Each step aligns with critical points in our color management program to ensure color accuracy and quality consistency for all customers.

Communication is equally essential. For international clients, we maintain close contact to meet specific color quality standards under G7 guidelines. With local clients, we take a collaborative approach, helping them understand the value of strict quality controls and how they enhance product reliability and competitiveness. This commitment to quality and transparency instills confidence in our service and compliance.

Capital Packaging has held G7 Master Certification for several years. What motivated you to pursue this certification, and what benefits have you experienced from it? Can you share any success stories since achieving G7 Master Certification?

We pursued G7 Master Certification to meet our clients’ demand for consistent, high-quality color management throughout production. G7 certification has been invaluable, not only boosting our credibility but also creating a standardized workflow that aligns all stakeholders to achieve precise color targets. This alignment is crucial for large projects requiring coordination across multiple teams and partners.

One notable success story with G7 certification involves our work in the packaging printing services for global electronics brands through RR Donnelley. By standardizing color across multiple contract manufacturing sites in Vietnam and China, we’ve ensured consistent quality and met strict standards, strengthening our customer relationships and building trust in our ability to deliver reliable, high-quality solutions across borders.

With your extensive experience in the printing industry, what trends and prospects do you see for the packaging printing market in Vietnam?

The packaging printing market in Vietnam is becoming highly competitive as more players enter, encouraged by favorable economic and global conditions. Simply acquiring certifications and meeting industry standards may no longer be enough to stand out. To remain relevant, companies need to leverage certifications and standards to add real value for customers. By applying certification standards to streamline processes and improve quality, companies can offer both credibility and added value, which gives them a competitive advantage.

At Capital Packaging, you place high importance on employee training and development. What efforts are you making to support this?

We regularly bring in specialists from leading printing companies for training on advanced tools and specialized skills in graphic and structural design. On-the-job training is a cornerstone of our approach, where senior technicians mentor the next generation, helping them deepen their expertise.

We also collaborate with Hanoi University of Science and Technology, offering internships that allow students to engage in hands-on production. This partnership, formalized in a 2024 cooperation agreement, includes annual scholarships for top students, and over the last three years, we’ve hired 11 graduates from this program.

Recently, Capital Packaging supported the training of the first G7+ Experts in Southeast Asia. Do you have a message to share with Idealliance members and customers?

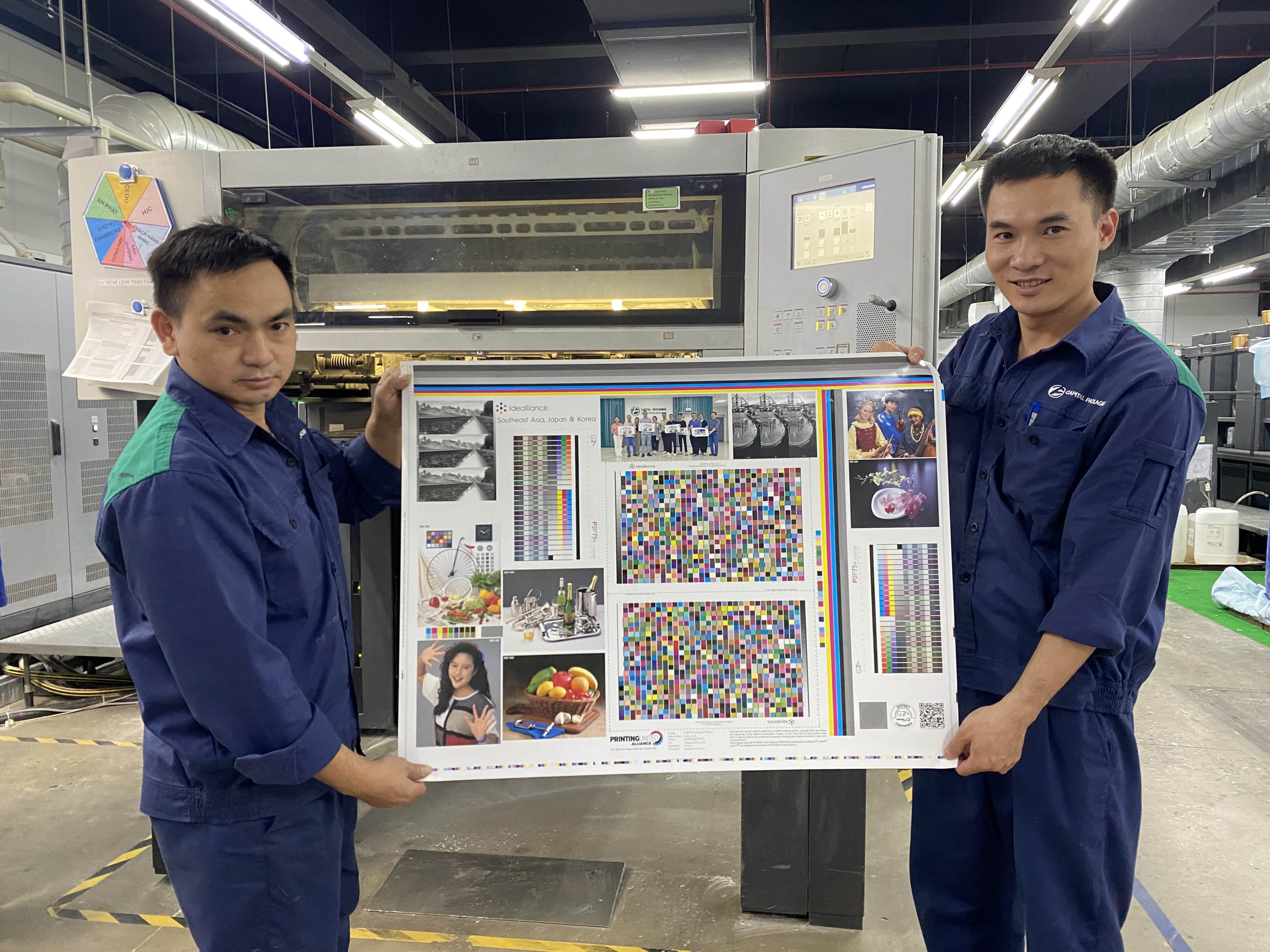

While we already have G7 certified technicians, we were eager to lead in Southeast Asia by completing the G7+ Expert course. Three of our young technicians completed the program in October, earning G7+ Expert certification. With this achievement, we’re focused on building an even stronger, more professional team that’s ready to meet evolving customer needs.

Lastly, what has been your most memorable print project and why?

One of our most memorable projects was a color management assignment with R.R.donnelley in spring 2023. They required printing to G7 standards, meeting CMYK and RGB color targets with dE00<1.5 and gray balance parameters<1 at a 300 LPI resolution. This project challenged us to improve from our previous 200 LPI limit and dE00<2.

To meet these standards, we worked closely with major suppliers, testing seven sets of mineral oil-free inks, and ultimately found a completely eco-friendly ink set that met all the criteria. We optimized every aspect of the process, including materials, printing conditions, and even room environment. Additionally, we acquired G7 multi-loop alignment techniques from our international colleagues. After two months of continuous improvement and rounds of evaluation, we became R.R.donnelley’s supplier in Vietnam. This project was a powerful learning experience, and it reinforced our commitment to taking on challenges, enhancing quality, and prioritizing customer satisfaction.

Author: Hye-Jeong Ahn(Idealliance Southeast Asia, Japan & Korea). All photos courtesy of Capital Packaging.

The author would like to thank Mr. Do Anh Vu Technical Advisor, Capital Packaging (Thu Do Packaging Joint Stock Company) for his contributions to this interview and to the industry through his role as a leader as a global print provider.

G7+™ and G7® are trademarks of PRINTING United Alliance. All other trademarks are property of their respective owners.