In Part 1 of this color management series, we reviewed how the press should be considered the “stake in the ground” for all devices to target. Whether it’s a specific press — that could be calibrated to G7 or something else, or not at all — or a Characterized Reference Printing Condition (CRPC), the point is that it serves as the common reference point for process color (CMYK) reproduction.

However, what’s behind the scenes and enables color to be managed very effectively across so many devices is the profile. Technically, it’s better known as the “ICC Profile,” meaning that the format and structure conforms to the

specifications outlined by the International Color Consortium (ICC), the independent body that oversees color management worldwide. The profile enables the connection between different color printing or imaging systems by quantifying the relationship

between CMYK output and a color space, namely the L*a*b* color space. In effect, it serves as a lookup table between the two: every possible combination of CMYK values and corresponding L*a*b* values.

In practice, an ICC profile is created based upon characterization data, meaning L*a*b* values as measured from some sort of color characterization chart. There are many to choose from, but the most popular and vendor-independent one is the IT8.7/5, also known as the TC1617 chart. This chart contains 1,617 CMYK patches, and while it doesn’t contain every possible combination of CMYK values (such a chart would be too large for practical purposes and isn’t necessary), it samples the CMYK color space very effectively, thereby enabling any CMYK output device to be modeled (characterized mathematically).

From there, an ICC profile can be created utilizing the characterization data and selecting a variety of settings or parameters (Total Area Coverage, GCR/UCR settings, black point settings, etc.). Then, for the purposes of creating a contract color proof,

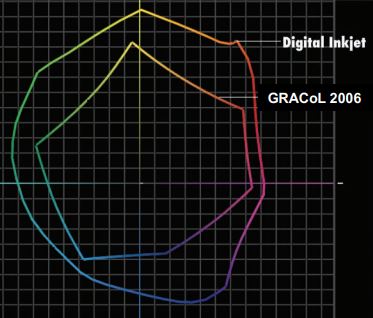

the profile is used to color manage the proofing system so that the proof very closely matches the targeted press or printing condition. Remember that inkjet printers can natively outperform most conventional CMYK printing technologies in terms of

producing saturated colors that exceed the capabilities of the press. So, beyond accurately reproducing within gamut colors, the profile also provides the information about the gamut boundary so that the inkjet printer/proofer doesn’t create

colors outside the gamut of the press.

Profiles can help with other processes (color conversions, etc.), but really serve as the backbone of all color management activities and, most importantly, achieving a match between the proof and the press. The trickier part is getting the press to consistently

repeat itself to the characterized printing condition, or stake in the ground, on which the profile is built and that the proof is targeting. We will address that in Part 3: "Process Control for Proof and Press."

PRINTING United Alliance and its Idealliance division provide color management and G7 standards trainings and certifications. Find an upcoming training by visiting printing.org/events/workshops.

As PRINTING United Alliance’s VP, Technical Services, Bill Pope leads educational initiatives, including the Continuous Improvement Conference and Technical Association of the Graphic Arts, while overseeing the Alliance’s consulting services and awards programs, and working closely with the newly merged team at Idealliance. With 30-plus years in printing and packaging, Pope frequently presents at industry conferences and events, and has authored numerous technical papers and articles for various journals and publications.

As PRINTING United Alliance’s VP, Technical Services, Bill Pope leads educational initiatives, including the Continuous Improvement Conference and Technical Association of the Graphic Arts, while overseeing the Alliance’s consulting services and awards programs, and working closely with the newly merged team at Idealliance. With 30-plus years in printing and packaging, Pope frequently presents at industry conferences and events, and has authored numerous technical papers and articles for various journals and publications.